Our team is proud to offer on time guarantee and product guarantee to customer satisfaction.

Read More

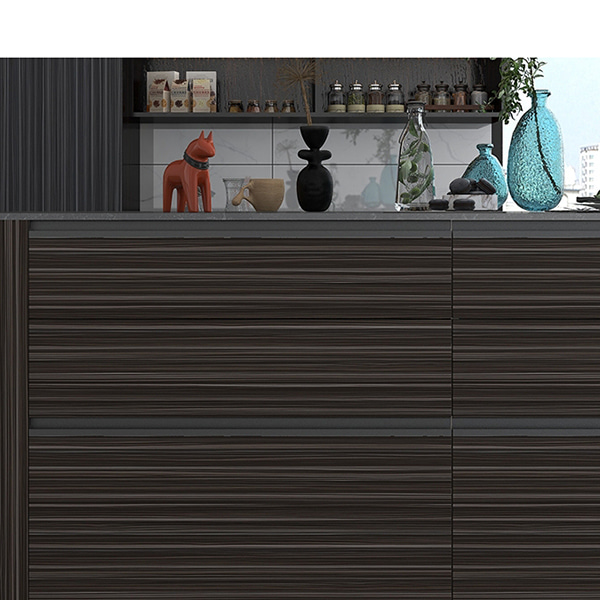

In modern furniture manufacturing and interior decoration, Wood Grain Decorative Papers have become an important surface decoration material to replace natural wood due to its realistic texture performance, flexible design adaptability and excellent cost control ability. However, in practical applications, how to improve its wear resistance, scratch resistance and anti-aging performance while retaining the natural wood texture is the key to measuring the quality of wood grain decorative paper.

1. Path to achieve natural wood texture

To make decorative paper present a visual and tactile effect close to real wood, it mainly depends on the process optimization of the following aspects:

1. High-precision printing technology

Modern wood grain decorative paper uses high-resolution digital scanning and bionic printing technology, which can accurately restore the texture direction, annual ring changes and color difference levels of natural wood, and even simulate natural defects such as insect bites and scars to enhance visual realism.

2. Multi-layer structure design

High-quality wood grain paper usually consists of three layers:

Surface printing paper: responsible for presenting fine wood grain;

Middle substrate layer: such as virgin wood pulp paper or special fiber paper, providing good ink absorption and flexibility;

Back reinforcement layer: enhances overall strength and prevents deformation or tearing.

This composite structure not only improves the clarity of printing, but also provides basic support for subsequent functional processing.

3. Surface embossing and touch simulation

Through hot pressing technology, a three-dimensional touch similar to wood texture can be pressed on the surface of the paper, allowing users to get a closer experience to real wood when touching.

2. Technological breakthrough in wear resistance and durability

Although wood grain decorative paper is essentially a paper material, its physical properties have been greatly improved through a series of post-processing processes, which is enough to cope with the wear and environmental challenges in daily use.

1. Impregnation and strengthening treatment

In the furniture and flooring industry, it is common to immerse wood grain paper in melamine resin or phenolic resin for drying and curing to form a hard and transparent protective film. This process can not only significantly improve wear resistance, but also enhance water resistance, high temperature resistance and anti-fading ability.

2. Scratch-resistant coating technology

Some high-end decorative papers are coated with nano-level wear-resistant coating or UV-curing varnish on the surface to effectively reduce scratch damage during daily use and maintain long-term beauty.

3. Anti-ultraviolet and anti-fading treatment

In order to deal with the color aging problem caused by light, wood grain decorative paper often adds light stabilizers and anti-UV coatings to ensure that the original color and texture can be maintained after long-term use.

4. Environmentally friendly function integration

In recent years, with the popularization of environmental protection concepts, some new wood grain papers have also integrated antibacterial, anti-mildew, low VOC release and other functions to meet the requirements of healthy homes and commercial spaces for air quality.

3. Balance considerations in application scenarios

Different uses have different requirements for the "texture" and "durability" of wood grain decorative paper:

Panel furniture: Focus on texture consistency and wear resistance, suitable for melamine impregnated paper;

Cabinet door panels: Emphasize waterproof and moisture-proof and easy to clean, and need to strengthen surface coating protection;

Wall decorative paper: Focus on visual beauty and environmental protection, and lightweight imitation wood grain paper can be selected;

Commercial space display: Pursue personalized customization and convenient installation, and recommend thermal transfer or self-adhesive wood grain paper.

Therefore, manufacturers need to reasonably configure material thickness, coating type and processing technology according to different terminal scenarios during product development to achieve the unity of natural wood texture and practical durability.

The reason why wood grain decorative paper can be widely used in the fields of artificial boards, furniture and decoration is that it can achieve a good balance between natural wood texture and wear resistance and durability. Through advanced printing, impregnation, coating and embossing technology, it not only achieves the aesthetic value comparable to solid wood, but also has industrial-grade practicality and environmental protection performance.

We focus on environmentally friendly, healthy, and fashionable home decoration, making your living space shine with unique charm.

Copyright © Hangzhou Xinyue Decorative Materials Co., Ltd. All rights reserved.

Custom Decorative Papers Manufacturers

English

English русский

русский عربى

عربى