Our team is proud to offer on time guarantee and product guarantee to customer satisfaction.

Read More

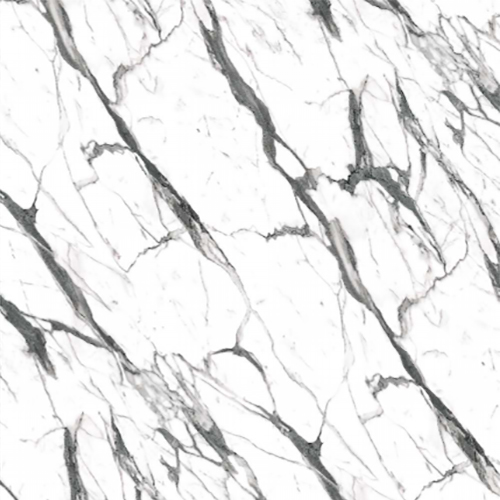

Stone pattern decorative papers are specialized surface materials that replicate the natural appearance of stone materials like marble, granite, slate, and travertine. These papers serve as cost-effective alternatives to genuine stone surfaces, offering the aesthetic appeal of natural stone at a fraction of the cost and weight. They're manufactured using advanced printing technologies that capture the intricate veining, texture variations, and color nuances found in authentic stone.

The global decorative paper market was valued at $3.2 billion in 2023, with stone pattern varieties representing approximately 18% of this segment due to their versatility in residential and commercial applications. These papers typically consist of multiple layers including a printed decorative layer, protective overlay, and adhesive backing, making them suitable for various surfaces including furniture, walls, countertops, and cabinetry.

Traditional decorative papers use cellulose-based substrates with high-resolution stone imagery. These papers are impregnated with melamine or phenolic resins to enhance durability and moisture resistance. Grammage typically ranges from 70-100 g/m², with thicker papers providing better opacity and coverage. They're commonly used in laminate production for furniture surfaces and flooring.

Vinyl-based stone pattern films offer superior water resistance and flexibility compared to paper alternatives. These films range from 0.1mm to 0.5mm in thickness and often feature embossed textures that add tactile realism to the visual stone pattern. They're particularly popular for kitchen backsplashes, bathroom applications, and outdoor furniture where moisture exposure is common.

High-quality stone pattern papers should exhibit resolution of at least 1200 dpi to accurately capture the fine details of natural stone veining and color variations. Examine the pattern repeat distance – premium papers have repeat patterns exceeding 120cm to avoid obvious repetition in large installations. Color accuracy is crucial; reputable manufacturers provide color matching to specific stone varieties like Carrara marble or Absolute Black granite.

Consider the following performance metrics when selecting decorative papers:

Different substrates require specific paper formulations. MDF and particleboard work well with standard melamine-impregnated papers, while metal surfaces benefit from papers with specialized adhesive systems. For curved or three-dimensional applications, select papers with elongation properties exceeding 3% to prevent cracking during forming processes.

Proper substrate preparation ensures optimal adhesion and longevity. The surface must be clean, dry, and smooth with irregularities not exceeding 0.5mm depth. For porous surfaces like raw wood or drywall, apply a primer-sealer to prevent air bubbles and ensure uniform adhesive distribution. Temperature should be maintained between 18-25°C during installation, with relative humidity below 65%.

For self-adhesive stone pattern papers, use the wet application method for repositioning flexibility. Spray the substrate with water-soap solution (ratio 500:1) before applying the paper, which allows up to 10 minutes of adjustment time before permanent bonding. Use a squeegee from center to edges at a 45-degree angle to eliminate air bubbles and excess moisture.

In laminate production, hot press methods apply papers to substrates at temperatures between 140-180°C with pressure ranging from 20-40 kg/cm² for 15-30 seconds. This process ensures complete resin cure and maximum bond strength.

When working with large surfaces requiring multiple sheets, achieving seamless pattern continuity is essential. Premium manufacturers provide registration marks for precise alignment. Overlap seams by 2-3mm before cutting through both layers simultaneously using a sharp blade and metal straightedge. This double-cut technique produces invisible seams when properly executed.

Stone pattern decorative papers, when properly installed and maintained, can last 10-15 years in residential applications and 7-10 years in high-traffic commercial environments. Regular maintenance involves gentle cleaning with pH-neutral cleaners and microfiber cloths. Avoid abrasive scrubbers, acetone-based solvents, and steam cleaners which can damage the protective overlay.

For surfaces exposed to direct sunlight, UV-protective topcoats can extend color vibrancy by an additional 3-5 years. Apply these coatings during initial installation or as periodic maintenance every 2-3 years. High-quality papers with built-in UV inhibitors show less than 2 Delta E color change after 1000 hours of accelerated weathering tests, equivalent to approximately 5 years of typical indoor light exposure.

Repair of damaged areas is straightforward with heat-activated adhesive systems. Small scratches often respond to manufacturer-supplied touch-up pens matched to specific stone patterns, while larger damages may require patch replacement using careful pattern matching techniques.

Stone pattern decorative papers offer significant environmental benefits compared to quarrying and processing natural stone. The carbon footprint of producing decorative paper is approximately 85% lower than equivalent natural stone extraction and fabrication. Modern manufacturers increasingly use recycled paper content (up to 30% post-consumer waste) and water-based inks to further reduce environmental impact.

From an economic perspective, the cost advantages are substantial. Material costs for stone pattern papers range from $2-15 per square meter depending on quality grade, compared to $80-300 per square meter for natural stone materials. Installation labor costs are reduced by 50-70% due to lighter weight, easier handling, and faster application times. A typical kitchen countertop renovation using stone pattern laminate can be completed in 2-3 hours versus 2-3 days for natural stone installation.

Transportation costs are minimized due to the lightweight nature of these materials – a roll containing sufficient paper for 50 square meters weighs approximately 8-12 kilograms compared to 2,500+ kilograms for equivalent stone coverage. This weight reduction also eliminates the need for structural reinforcement required when installing heavy natural stone surfaces.

We focus on environmentally friendly, healthy, and fashionable home decoration, making your living space shine with unique charm.

Copyright © Hangzhou Xinyue Decorative Materials Co., Ltd. All rights reserved.

Custom Decorative Papers Manufacturers

English

English русский

русский عربى

عربى